Substrates:

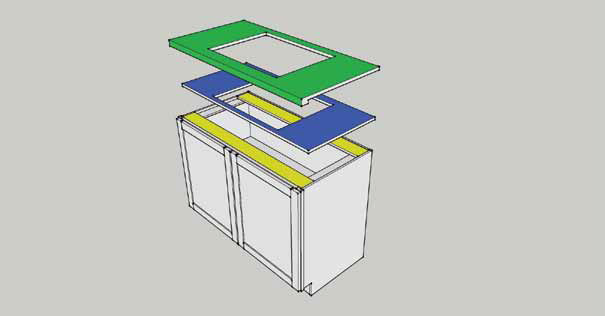

Stone countertops should not be directly installed onto open cabinet carcasses. For countertops with edges thicker than the standard 20mm, substrates (typically made of 18mm MDF) must be attached to the top of all cabinet carcasses to support the weight of the stone countertop (see diagram below). These substrates must be level to ensure the stone remains flat. On each exposed side of the stone, the substrate should be offset by 25mm (for mitred edges) or 45mm (for laminated edges) from the desired finished edge.

To install the substrate, use small “L-brackets” screwed into the cabinet carcass from beneath the substrate. This way, if the stone ever needs to be moved or replaced, it can be removed without damaging the carcass.

Cut-outs for sinks, cooktops, tap holes, waste holes, etc., must be made in the substrate before the stone is installed. Undermount sinks should be recessed into the substrate, allowing for a 5mm movement in all directions. A rail on the edge, front, and back of hot plates, sinks, and dishwashers must be installed (see diagram below).

For benches with a 20mm edge, a top on each cabinet carcass, with particular attention to rails, is required, as indicated in the diagram. A maximum span of 600mm is allowed. Alternatively, a substrate can be used and finished in the same material as your cabinetry to create a shadow line effect. Please discuss support options with your cabinetmaker (and/or refer to INFORMATION SHEET B). An overhang of up to 150mm can be achieved without a substrate support.

Templates and substrates are usually provided by your cabinetmaker. In the case of flat-pack style cabinets and renovations, you may need to arrange for the supply of these items separately. It is advisable to have these produced professionally as our quote includes one site visit for template check measure and/or collection, and one installation visit. Additional charges will apply for extra check visits or on-site modifications to countertops.

Please note that countertops cannot be installed flush with adjoining walls/panels, as stone can expand and contract and requires a suitable gap. This also applies to countertops that adjoin freestanding ovens.

Templates:

Templates are a pattern of the desired countertop(s) and should be provided to Multiform Stone by the customer. Typically, these templates are made from 3-4mm thick MDF timber and should match the exact size and shape of the finished stone product. Appliance, sink, and tap/water filter tap hole locations and sizes must also be indicated and cut out on the template and substrate. All dimensions should be clearly marked on the front face. Include the client’s name, installation address, product details (brand and stone name), and edge style. Mark edges to be polished with X for edges.

Base cabinets should be complete, in place, and structurally sound before constructing templates to ensure an accurate fit, especially when the countertop adjoins a wall or fixed panel.

Once templates are ready, we can process your order and provide an estimated delivery/installation date. A Multiform Stone team member will arrange an appointment to perform a “laser check measure” of your templates onsite and may take them, along with any undermount sinks/basins, to our factory (determined by our template measurer during the appointment).

For countertops with undermount sinks, precise cut-outs are required. Include sink model numbers, brand, and mounting instructions on the relevant template, such as “cut out edge flush with sink” or “exposed lip of 10mm.” Customers must also provide the sink and any accessories (e.g., drainage bowls, cutting boards) during the check measure appointment.

At this stage, a 50% deposit of the quoted price will be necessary.