Frequently Asked

Please be aware that the following information represents the most current details available from our various material suppliers and may be subject to change without prior notice.

- Granite, Marble & Reconstituted Stone For natural stone and engineered stone products like Caesarstone, Silestone, Smartstone, Quantum Quartz, etc., with nominal 20mm slabs featuring a 20mm edge or mitred/laminated apron/edge profile:

- Overhangs of up to 150mm without additional support are permitted in 20mm material to allow for a finished 20mm edge. For overhangs exceeding 150mm, substrates are necessary.

- Extra support rails are required on edges adjacent to underbench ovens, sinks, and dishwashers.

- Up to a 300mm overhang is permissible without requiring additional support (18mm substrates are sufficient) at intervals of 600mm or less.

- Overhangs exceeding 300mm necessitate brackets, legs, or a metal frame to support the substrates.

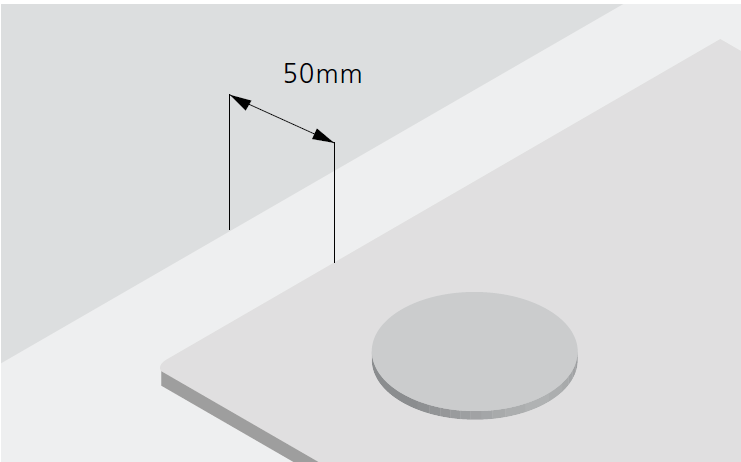

- A minimum of 80mm is required between the front edge of the benchtop and cutouts such as sinks or hotplates. A minimum of 50mm is needed from the rear of the benchtop to cutouts. A minimum distance of 35mm must be maintained between sink and tap cutouts.

- Porcelain 12mm Panels (DEKTON, INFINITY, LAMINAM, NEOLITH & QUANTUM SIX+ 12mm)

- 12mm panels require full 18mm substrates. Mitred edges of 40mm require 26mm substrates.

- Overhangs of up to 150mm with no additional support are allowed in 12mm material to create a finished 12mm edge. For overhangs exceeding 150mm, substrates are required.

- For 40mm mitred edges, substrates must be 8mm thicker than usual, i.e., 26mm substrates instead of 18mm.

- A minimum distance of 50mm must be maintained from each cutout, both from the edge to the cutout and between cutouts.

- Undermount sink cutouts should be the same size as the sink or rebated, meaning the material should not overhang.

- Drainage grooves, drainage sections, and flush mounting for appliances are not feasible with these panels.

- Porcelain 5, 6, or 8mm Panels

- These panels are exclusively intended for use as splashbacks or other vertical surfaces and are not suitable for benchtop applications.

- Porcelain 20mm Panels

- 20mm panels do not require substrates. However, back-to-front supports must be fabricated every 600mm and installed around the perimeter of cutouts larger than 600mm.

- The standard overhang for 20mm panels is 300mm. Additional support in the form of MDF substrates (or similar) will be necessary for overhangs exceeding 300mm.

- A minimum distance of 50mm must be maintained from each cutout, both from the edge to the cutout and between cutouts.

- Undermount sink cutouts should not overhang sinks; they should be rebated or level with the sink.

- Drainage grooves and drainage sections are possible but must be limited to a maximum of 25% of the material, i.e., a maximum of 5mm in 20mm material. Flush mounting of hot plates is also possible but will result in rounded corners, not square ones as typically seen on most appliances.

Substrates:

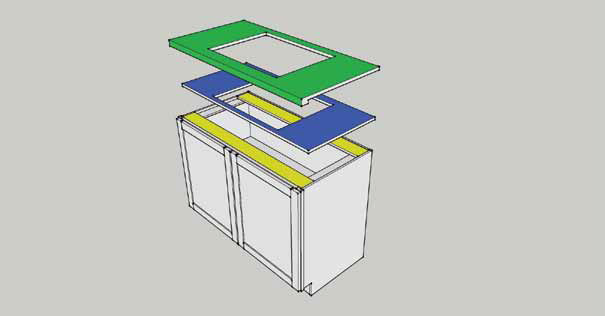

Stone countertops should not be directly installed onto open cabinet carcasses. For countertops with edges thicker than the standard 20mm, substrates (typically made of 18mm MDF) must be attached to the top of all cabinet carcasses to support the weight of the stone countertop (see diagram below). These substrates must be level to ensure the stone remains flat. On each exposed side of the stone, the substrate should be offset by 25mm (for mitred edges) or 45mm (for laminated edges) from the desired finished edge.

To install the substrate, use small “L-brackets” screwed into the cabinet carcass from beneath the substrate. This way, if the stone ever needs to be moved or replaced, it can be removed without damaging the carcass.

Cut-outs for sinks, cooktops, tap holes, waste holes, etc., must be made in the substrate before the stone is installed. Undermount sinks should be recessed into the substrate, allowing for a 5mm movement in all directions. A rail on the edge, front, and back of hot plates, sinks, and dishwashers must be installed (see diagram below).

For benches with a 20mm edge, a top on each cabinet carcass, with particular attention to rails, is required, as indicated in the diagram. A maximum span of 600mm is allowed. Alternatively, a substrate can be used and finished in the same material as your cabinetry to create a shadow line effect. Please discuss support options with your cabinetmaker (and/or refer to INFORMATION SHEET B). An overhang of up to 150mm can be achieved without a substrate support.

Templates and substrates are usually provided by your cabinetmaker. In the case of flat-pack style cabinets and renovations, you may need to arrange for the supply of these items separately. It is advisable to have these produced professionally as our quote includes one site visit for template check measure and/or collection, and one installation visit. Additional charges will apply for extra check visits or on-site modifications to countertops.

Please note that countertops cannot be installed flush with adjoining walls/panels, as stone can expand and contract and requires a suitable gap. This also applies to countertops that adjoin freestanding ovens.

Templates:

Templates are a pattern of the desired countertop(s) and should be provided to Multiform Stone by the customer. Typically, these templates are made from 3-4mm thick MDF timber and should match the exact size and shape of the finished stone product. Appliance, sink, and tap/water filter tap hole locations and sizes must also be indicated and cut out on the template and substrate. All dimensions should be clearly marked on the front face. Include the client’s name, installation address, product details (brand and stone name), and edge style. Mark edges to be polished with X for edges.

Base cabinets should be complete, in place, and structurally sound before constructing templates to ensure an accurate fit, especially when the countertop adjoins a wall or fixed panel.

Once templates are ready, we can process your order and provide an estimated delivery/installation date. A Multiform Stone team member will arrange an appointment to perform a “laser check measure” of your templates onsite and may take them, along with any undermount sinks/basins, to our factory (determined by our template measurer during the appointment).

For countertops with undermount sinks, precise cut-outs are required. Include sink model numbers, brand, and mounting instructions on the relevant template, such as “cut out edge flush with sink” or “exposed lip of 10mm.” Customers must also provide the sink and any accessories (e.g., drainage bowls, cutting boards) during the check measure appointment.

At this stage, a 50% deposit of the quoted price will be necessary.

Stone benchtops can be extended up to 300mm with support solely from a substrate. If you need an overhang beyond this width, you will require additional support, which can take the form of brackets or a metal support frame (for overhangs between 300mm to 500mm), or legs, columns, or panels (for overhangs exceeding 500mm). When requesting a quotation, please consult with us, and we will gladly provide you with more information regarding the necessary support requirements.

The installation of stone products, especially granite and marble, can generate mess, notably in the form of fine stone dust. To mitigate this, we highly advise clearing the installation area of as many items as possible and employing dust sheets to shield non-movable objects. You can also use dust sheets to cover doorways leading to adjacent rooms, preventing the dust from spreading into those areas. While our installers will make every effort to minimize the mess, there may still be some residual inconveniences from the installation process.

Certain customers may wish to keep their cutouts (formed for sinks, hotplates, etc.) for future use. It’s important to be aware that these cutouts will have unrefined edges. If you desire the cutouts to be smoothed and polished for potential use, kindly specify your preferences, along with the dimensions, when placing your order and make sure these details are documented on your templates. Our estimators will furnish you with a price for this service, which can be integrated into your initial quote or added either before or during the template measurement stage.

The resin or adhesive used to affix your stone benchtop to the substrate requires a minimum of 24 hours to fully harden and set. To ensure the stability and structural integrity of your bench, it is advisable to schedule your plumber’s visit for at least two days after the bench installation to allow this curing process to take place. This guideline also applies to inset cooktops. Additionally, it is recommended that splashbacks be installed no sooner than two days after the stone installation.

Please communicate to any tradespeople arriving after your stone installation that they should refrain from sitting or standing on the benches, and that the stone should be safeguarded while they work nearby. It is important to continue treating your benches with care by refraining from standing or sitting on them at any time.

You will need to register your warranty with the company that manufactured your stone, generally within 30 days of installation:

| Stone Supplier | Warranty Link |

|---|---|

| Caesarstone | https://www.caesarstone.com.au/warranty-form/ |

| Quantum Quartz | https://www.wk.com.au/Contact/WarrantyRegistration |

| YDL Stone | https://www.ydlstone.com.au/warranty-registration/ |

| RHF Stone | https://www.rhfstone.com.au/technical-info/ |

| Stone Ambassador | https://www.stoneambassador.com.au/warrantyregistration/ |

| Lavistone | https://lavistone.com.au/warranty/ |

Delivery and/or installation by AB Stone will take place within a maximum of 10 working days after receiving the template-ready notification and the deposit payment. Please keep in mind that during certain periods, such as the pre-Christmas season, a longer time frame may be expected.

Final payment is required prior to installation. Please enquire about payment methods when your installation is arranged.

Electric Cooktops & Induction Cooktops

For optimal safety and functionality, we advise maintaining a minimum 50mm distance between the rear edge of both electric and induction cooktops and the splashback.

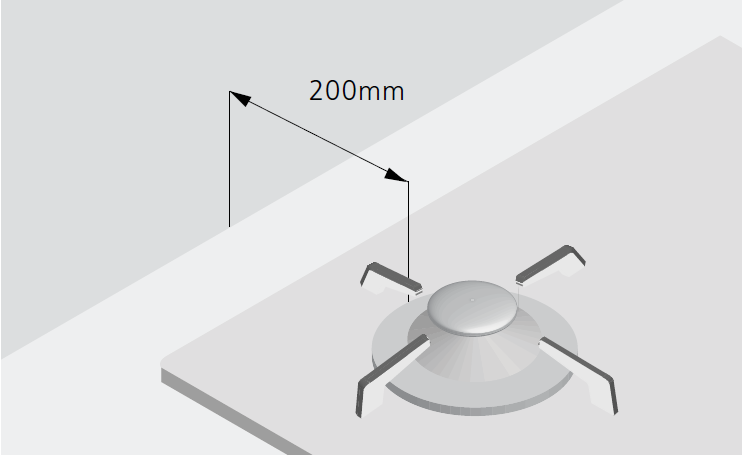

Gas Cooktops

For gas cooktops, we suggest maintaining a minimum 200mm distance from the outer edge of the gas burner to the Splashback for safety and performance.

Undermount Sink

Undermount sinks offer an excellent choice for those seeking a modern and streamlined kitchen aesthetic. The term “under mount” refers to their positioning below the standard height of countertops. While they do require some extra effort to install, the stunning appearance of these under cabinet sinks makes the additional work well worthwhile.

Topmount Sink

We’re familiar with the two main sink types: drop-in and top mount. But what distinguishes them? Top mount sinks, also known as over mount or bench top sinks, rely on a lip to support their weight atop the counter. Conversely, undermount sinks are set into the cabinet below.

Drop-in sinks are a fantastic option for any household due to their versatility and adaptability. Available in porcelain, granite, or stainless steel, they offer a range of choices to suit your preferences perfectly!

Care and Cleaning